Aluminium anode is a type of anode that can be used safely in all types of water. It has very high current capacity which makes it very attractive in terms of cost and weight saving. It is highly recommended for use in low resistivity applications. However they can also be used for effective corrosion protection to the structure in fresh and brackish water.

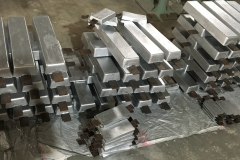

They also have a particular use in the protection of subsea pipelines, oil rigs and semi submersibles. We offer these anodes in various shapes and sizes (Flush Mounted, Ship hull, offshore platform etc.) to meet the specific requirements of the clients.

Chemical Composition

| Standard | Indium | Cadmium | Silicon | Copper | Others | Zinc | Iron | Aluminium |

|---|---|---|---|---|---|---|---|---|

| GALVALUM III | 0.01-0.02% | – – | 0.08-0.20% | 0.006% Max | 0.10% Max | 2.0-6.0% | 0.13% Max | Remainder |

| DNV RP B401 | 0.015-0.040% | 0.002% Max | 0.12% Max | 0.003% Max | 0.10% Max | 2.5-5.75% | 0.09% Max | Remainder |

| GS EP COR 201 | 0.015-0.030% | – – | 0.10% Max | 0.005% Max | 0.10% Max | 2.5-6.0% | 0.09% Max | Remainder |

Except the above standard composition, we also manufacture various other compositions to suite the requirement of the different size and structure. Aluminium Anode has a longer life compared to Magnesium and Zinc Anode because of better Open circuit potential & better Anode Current capacity. Higher the Current Capacity, lower would be the consumption of the Anode hence, consumption rate of Aluminium Anode is 3.4 kgs / Amp Yr whereas Consumption rate of Zinc and Magnesium is 11.4 kg/Amp.Yr and 7.9 Kg/Amp.Yr respectively.

Open Circuit Potential: -1.07 V (Ag/AgCI reference cell)

Anode Capacity : 2550 Amp. Hr/Kg.

Consumption Rate : 3.4 Kg./Amp. Yr.

STEEL CORE

The anode cores are made out of low carbon structural steel corresponding to IS 2062 suitable for welding, with a carbon equivalent of less than 0.45%, shot blasted prior to casting.

Shakti Anodes are produced from high purity base materials and designed for optimum performance under various environments.

Last Updated on: